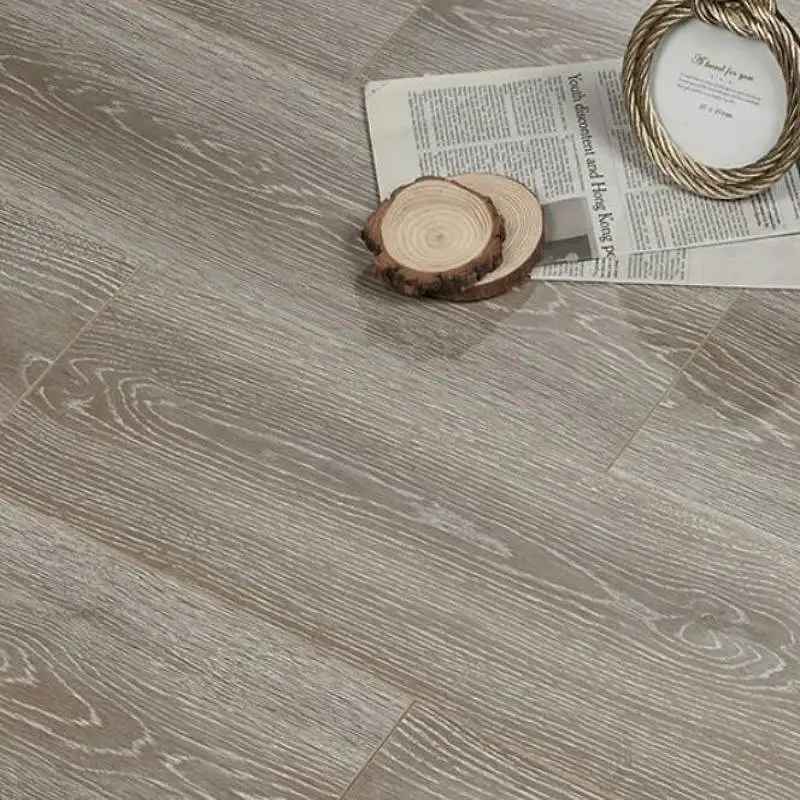

The Impact of Density on Laminate Flooring Installation and Longevity

Laminate flooring has become a popular choice for homeowners and designers due to its affordability, aesthetic versatility, and ease of installation. While many people focus on the thickness and design of laminate flooring, another crucial factor that significantly impacts its performance and durability is its density. This article delves into the importance of laminate flooring density, how it is measured, and what homeowners should consider when selecting the right laminate flooring for their needs.

Flooring is the general term for a permanent covering of a floor, or for the work of installing such a floor covering. Floor covering is a term to generically describe any finish material applied over a floor structure to provide a walking surface. Both terms are used interchangeably but floor covering refers more to loose-laid materials.

What is Laminate Flooring Density?

Density in laminate flooring refers to the mass of the material per unit volume, typically measured in kilograms per cubic meter (kg/m³) or pounds per cubic foot (lb/ft³). It is a critical factor that influences the flooring’s durability, stability, and overall performance. Higher density laminate flooring tends to be more robust and resistant to impacts, while lower density options may be lighter and less durable.

How is Density Measured?

The density of laminate flooring is determined by the core material used in its construction. Most laminate flooring consists of a high-density fiberboard (HDF) or medium-density fiberboard (MDF) core, which is sandwiched between a decorative layer and a protective wear layer. The density of the core material is a key indicator of the flooring’s overall quality and performance.

- High-Density Fiberboard (HDF): HDF cores typically have a density of around 800-900 kg/m³ (50-56 lb/ft³). This high density makes HDF laminate flooring more durable, stable, and resistant to moisture and impacts.

- Medium-Density Fiberboard (MDF): MDF cores usually have a density of around 600-800 kg/m³ (37-50 lb/ft³). While MDF laminate flooring is generally less expensive, it may not offer the same level of durability and moisture resistance as HDF options.

Choosing the Right Density for Your Needs

When selecting laminate flooring, homeowners should consider the specific needs of their space and lifestyle. Here are some general guidelines:

- High-Traffic Areas: For areas with heavy foot traffic, such as living rooms, hallways, and kitchens, opt for high-density laminate flooring with an HDF core. This will ensure maximum durability and impact resistance.

- Moisture-Prone Areas: In spaces like kitchens and bathrooms, where moisture exposure is a concern, choose high-density laminate flooring with enhanced moisture resistance.

- Budget Considerations: If budget constraints are a primary concern, medium-density laminate flooring with an MDF core can be a cost-effective option for low-traffic areas such as bedrooms and home offices.