Types of presses commonly used in refractory brick production workshops

In the production process of refractory bricks, the molding process is its most important part. When producing refractory bricks, the entire molding process setting is often related to the product density. Under the premise that there is no problem with the raw materials, the general product density meets the prescribed requirements that there is basically no problem with other indicators. For this reason, we generally control production according to the density of bricks. The types of presses commonly used in refractory brick production can be basically divided into three categories:

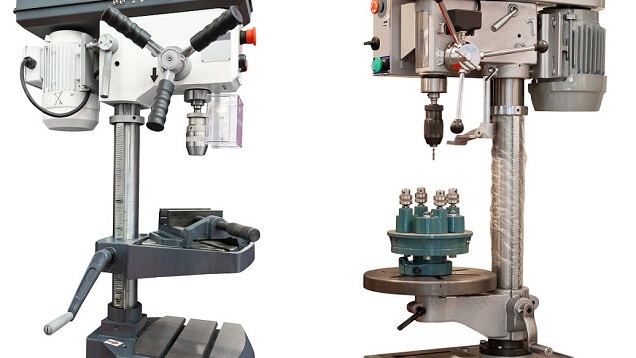

1. Friction press

Friction press is also called double-disc friction press. They mainly rely on friction to transfer energy, hence the name. During work, the vertical and flat wheels rub against each other, lift the slider, store energy, and then release it to generate impact pressure. The whole process is simple and clear. The structure, operation and auxiliary equipment of the friction press are very simple, and the price of the accessories is low, so that it is very easy to accept whether it is the procurement cost or the training of the operator and maintenance worker. Therefore, many industries such as machinery manufacturing, automobile manufacturing, forging and refractory are widely used.

At present, the main friction press models commonly used in the refractory brick production workshop are: J67-300T, 400T, 630T, 1000T, 1600T; J93-400T, 630T, 1000T, 1600T, such as J93 Series Refractory Friction Screw Press For Brick, J67 Series Refractory Friction Screw Brick Press Machine, etc.

2. Electric screw press

The electric screw press is a new type of forging equipment with wide application and strong applicability. Its structure is simple and its capacity is large. In order to facilitate the later mold design, the slider designed by the electric screw press has no bottom dead center. Both are very simple. The electric screw press can be used not only for hot forging, but also for precision forging and finishing, with a wide range of applications, such as various precision forging, finishing, precision pressing, embossing, correction, calibration, and forging precision .

The electric screw press is small in size, without vertical wheels, simple in operation, safe in operation, and accurately adjustable in striking force, so the mold wear rate is low, the maintenance cost in the later period is low, and the workload is small. The electric screw press is well-designed, the guide precision of the slider is high, and the ability to resist eccentric load is strong, which is very suitable for multi-station die forging. According to the needs of the use environment, there are two types of transmission methods for the electric screw press. One is the belt drive, and the belt-driven electric screw press has good shock resistance; the other is the gear drive, and the gear-driven electric screw press has good rigidity.

3. Hydraulic press

The hydraulic press is a fully automatic equipment controlled by PLC, which is a combination of mechanical, electrical and hydraulic. It is mainly composed of the following modules: hydraulic system, electrical control system, mechanical system, human-computer interaction system. Through the cooperation of various modules to achieve the work of feeding, pressurizing, mold release, brick clamping and so on.

The presses for the production of the above three types of refractory bricks have their own characteristics and their own advantages and disadvantages. Therefore, customers need to choose according to their actual production needs and capabilities.