Advantages and disadvantages of mechanical and hydraulic presses

Mechanical press is a forging machine driven by a crank link or toggle lever mechanism, cam mechanism, and screw mechanism. It is a machine tool for pressure processing of materials. It is processed by applying strong pressure on the blank to deform and break it. Components.

Compared with mechanical transmission, hydraulic transmission has many technical advantages such as large power-to-mass ratio, convenient stepless speed regulation and overload protection, and flexible and convenient layout.

So, What are the main advantages and disadvantages of mechanical and hydraulic presses?

1. The hydraulic press uses a hydraulic pump to generate power through the control circuit hydraulic actuator to transmit power. The liquid meson has water and emulsion; hydraulic oil. It is characterized by high working pressure, stable operation, free control of working stroke, large adjustment range, large working space, and moderate working efficiency. It can complete most of the work of mechanical press machine and has a wide range of applications. The configuration of the hydraulic press is more complicated. The larger presses are generally equipped with independent pumping stations, the control parts and circuits are more complicated, and the cost is relatively high.

2. From the perspective of the mold, the hydraulic press is suitable for large, complex and precise automotive sheet metal parts, especially with a “stretch” function. Suitable for large cover parts and door parts of automobiles. Its characteristics are relatively dense compared to mechanical presses, and the stability of product structure and size is better. Maintenance is more convenient than mechanical presses, because of the standardization of hydraulic parts, the maturity of the theory is very high. For example, to find faults, you can draw wings from a hydraulic schematic diagram. Just insist on using genuine hydraulic oil.

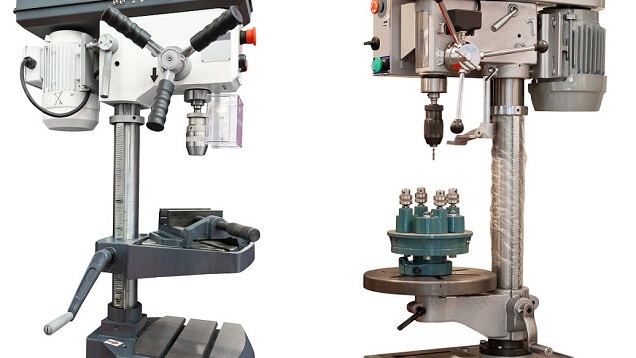

3. The crank-arm press uses the crank arm to transmit force, which is characterized by fast running speed and high working efficiency, and the working stroke is fixed and cannot be adjusted. It is strictly forbidden to overload operation. Generally used for blanking, punching, stretch forming, etc.

The friction screw presses use the wheel to drive the friction wheel to transmit the force by the inertia rotating screw, which is characterized in that it is not restricted in the effective working area of the screw, the transmission pressure is large, and the work efficiency is moderate. The operation is not easy to control. Generally used for material correction; simple molding; die-casting cavity molding. Shuangdong press is mainly used for stretch forming. It relies on the screw to transmit force directly.

Mechanical press 1. fast operation, high efficiency, low cost, simple control part, easy maintenance; 2. small work surface, generally equipped with counterweight wheels (flywheels) to increase its transmission power Noise and vibration.

Compared with mechanical transmission, hydraulic transmission has a large power / mass ratio, which is convenient for stepless speed regulation and overload protection, flexible and convenient layout and other technical advantages. Mechanical presses are fast, but their strength is not as large as hydraulic presses. Hydraulic presses are heavy but slow.